language

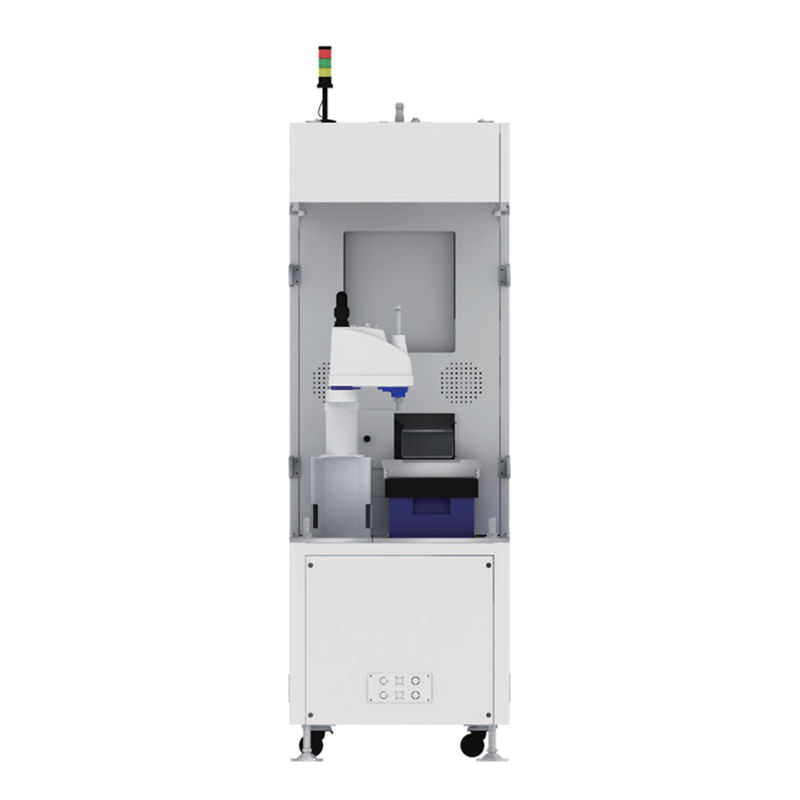

One-to-one flexible loading station FFW-S-240D

One-to-one flexible loading station FFW-S-240D

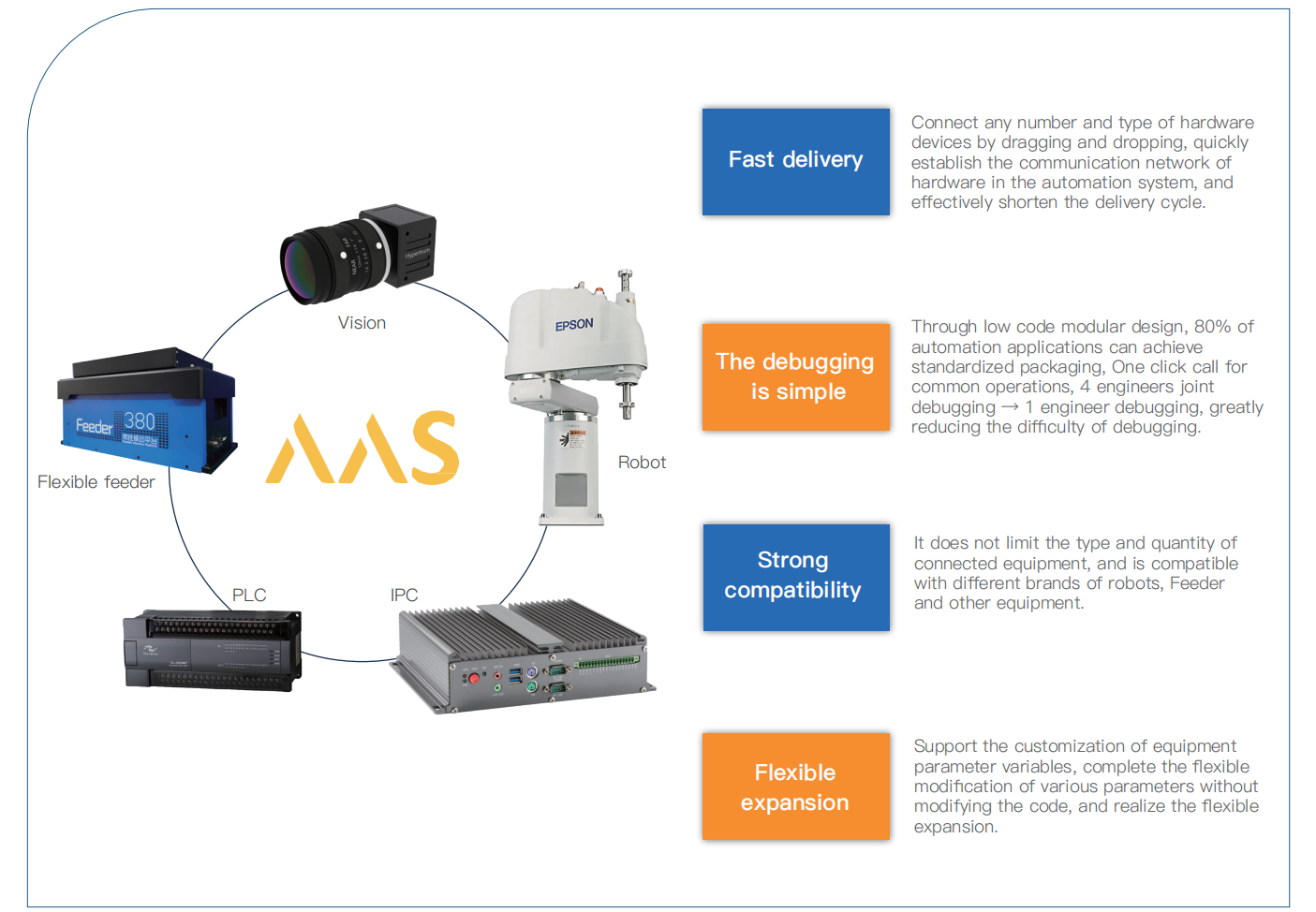

The Flexible Feeding Station is managed through our proprietary AAS integrated software for unified control. It enables one-click communication among vision systems, flexible vibratory feeders, robotic arms, PLCs, and industrial PCs, facilitating the rapid construction of automation applications. This significantly reduces the integration cycle and debugging complexity of flexible feeding systems, thereby lowering costs.

Specification

|

Model |

FFW - S - 240D |

|

Applicable Part Size |

5 - 15 mm |

|

Picking Area |

155*195 mm |

|

Picking Height |

850 mm |

|

Rack Size |

6009002000 mm |

|

Light Source |

200*190 mm |

|

Feeding Accuracy |

± 0.1 mm |

|

Atmospheric Pressure |

0.5 - 0.7 mpa |

|

Voltage |

220 V |

|

Power |

1000W |

|

Communication Protocols |

TCP/IP, Modbus TCP, IO |

|

Flexible Feeder |

FF240D |

|

Plate Size |

195*151 mm |

|

Hopper Volume |

8 L |

|

Width Of The Outlet |

120 mm |

|

CCD Camera (Hikvision) |

500W/1200W |

|

Vision Software |

TEAM AAS Ver 3.0 |

|

Manipulator Model |

EPSON LS3,T3 |

|

Manipulator Reach |

400 mm |

|

Manipulator Load |

3 kg |

|

IPC |

ADVANTECH |

|

Grippers / Nozzles |

Customize |

|

Caching Mechanism |

Optional |

|

Secondary Positioning |

Optional |