language

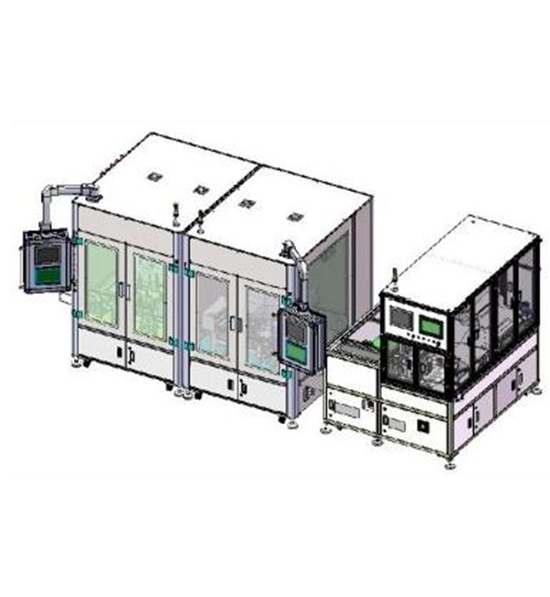

Socket LN Pole Assembly Station

O-ring Flexible Feeding

Assembly Station Socket LN Pole

Assembly Station High-Volume Flexible

Automated Production Line Low-Volume Flexible

Automation Production Line Intelligent Locking

Of Camera Module Small-Scale Energy

Storage Self-Tapping

Screw Fastening

Workstation Medical Consumables

Flexible Assembly

Equipment Medium-Volume

Flexible Automated

Production Line Automatic Sorting

Tray Workstation

Assembly Station Socket LN Pole

Assembly Station High-Volume Flexible

Automated Production Line Low-Volume Flexible

Automation Production Line Intelligent Locking

Of Camera Module Small-Scale Energy

Storage Self-Tapping

Screw Fastening

Workstation Medical Consumables

Flexible Assembly

Equipment Medium-Volume

Flexible Automated

Production Line Automatic Sorting

Tray Workstation

Socket LN Pole Assembly Station

The combination solution for feeding materials onto the socket base and assembling the L/N level, including flexible feeding, robotic arm, pusher machine, and material bin, provides high compatibility, solving the issue of frequent manual feeding.

Composition Of The Solution

Core components

| Project | Technical Parameters | |

| Equipment Size | 4390*1910*1900mm | |

| Communication Method | TCP/IP | |

| Power Supply | AC 220V 50HZ 20A | |

| Air Supply | Positive Pressure:≥0.5MPa | |

| Environment | Temperature:5~40℃;Humidity:RH10~80% | |

| CCD | Resolution:12million pixels | |

| Robot Arm Repeatability | Arm Length:400mm 1st, 2nd Joints:±0.02 mm 3rd Joint:±0.01 mm 4th Joint:±0.01mm Load:4KG |

|

| CT | 2.5s | |

| Assembly Accuracy | ±0.03mm | |

| OEE | >90.0% | |

| Yield Rate | 99.7% | |

| Weight | 3500Kg | |

| Power | 4KW | |

| CPK | 1.67 | |

| ROI | 1.5years | |

Videos

.jpg?x-oss-process=image/resize)