language

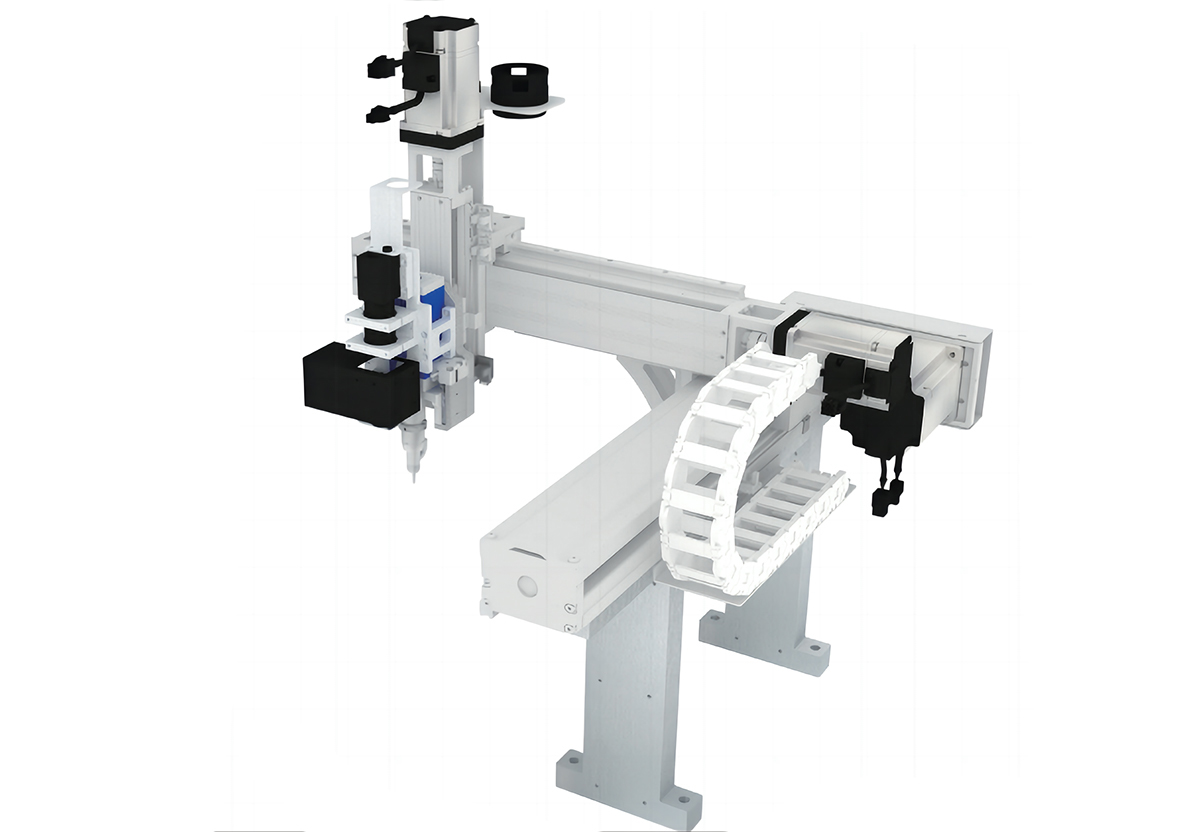

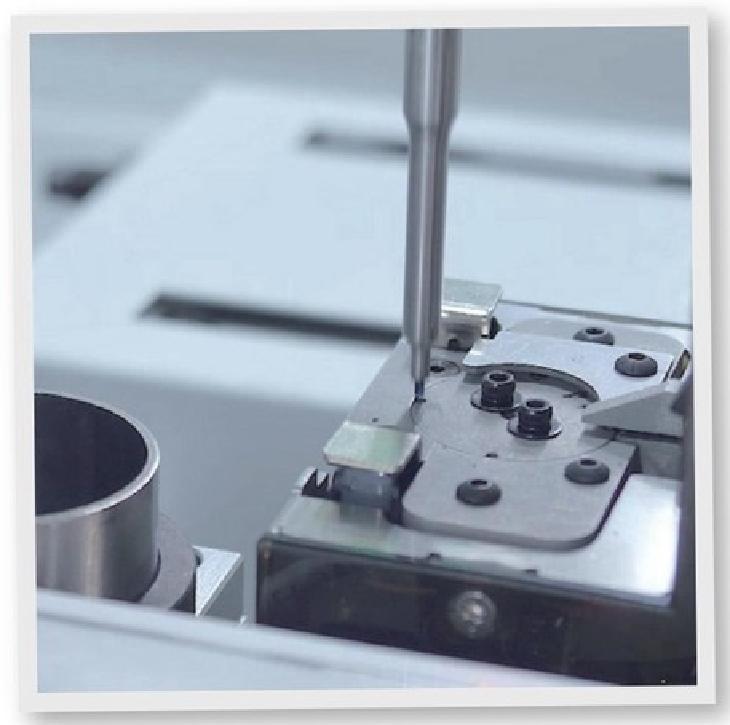

Three-axis Robot Screw Machine

Three-axis Robot Screw Machine

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Information

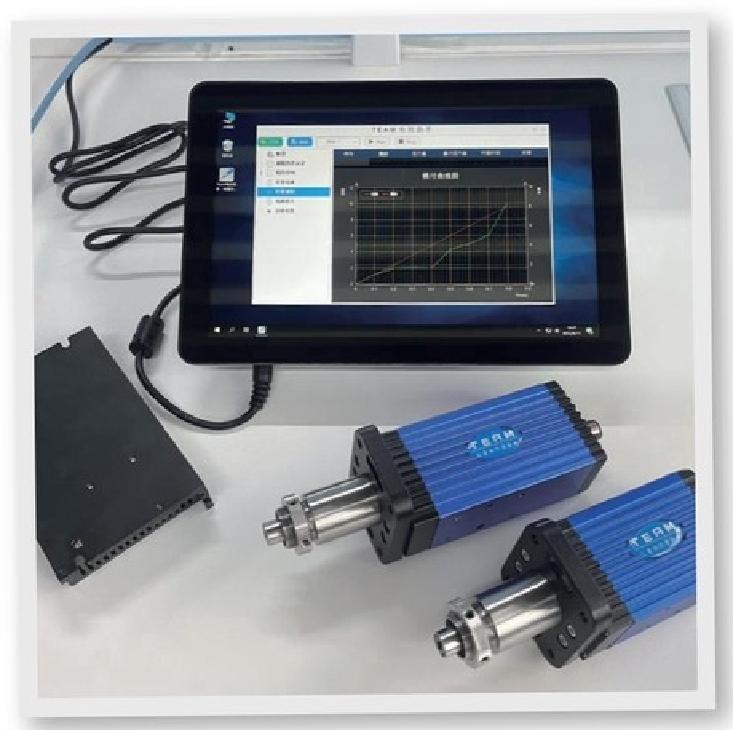

| Basic parameters | |

| Screw Specifcation | M0.6~M8 |

| Power | 900 W |

| Power Supply | AC 220V |

| Repeatability | ±0.02mm |

| Arm Length | X-axis 100~700mm Y-axis 100~300mm Z-axis 100mm |

Speed Of Movement |

X/Y axis 1000 mm/s Z-axis 500 mm/s |

| Optional | |

| Secondary Localization Vision | 00 No /01 Yes |

| Moving Vision | 00 No/01 Yes |

| Floating Height Detection | 00 No/01 Yes |

| Automatic torque calibration | 00 No /01 Yes |

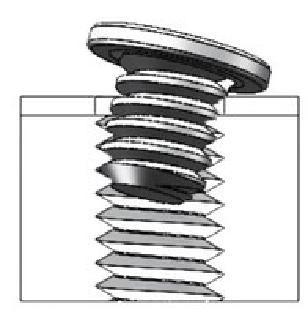

Screw tigntening robot Manual tightening screws

| 1.5~3s/pcs | EFFICIENCY | 5s/pcs | |||

| 0~1/people | MANPOWER | 2~3/people | |||

| Up to 99.95% | YIELD | It varies from person to person | |||

| Real-time monitoring of the whole process of tight payment and timely alarm in case of abnormality |

EXCEPTION HANDLING |

Manual detection is uncontrollable | |||

| High-precision torque control,real-time data monitoring and adjustment |

TORQUE CONTROL |

Rely on employee experience | |||

| Stable operation and almost no management cost | MANAGEMENT COSTS | High turnover rate,uneven quality of personnel and high management cost |

|||

| One-time investment without continuous investment |

INPUT COST |

Continuous investment |

Application Industry

-

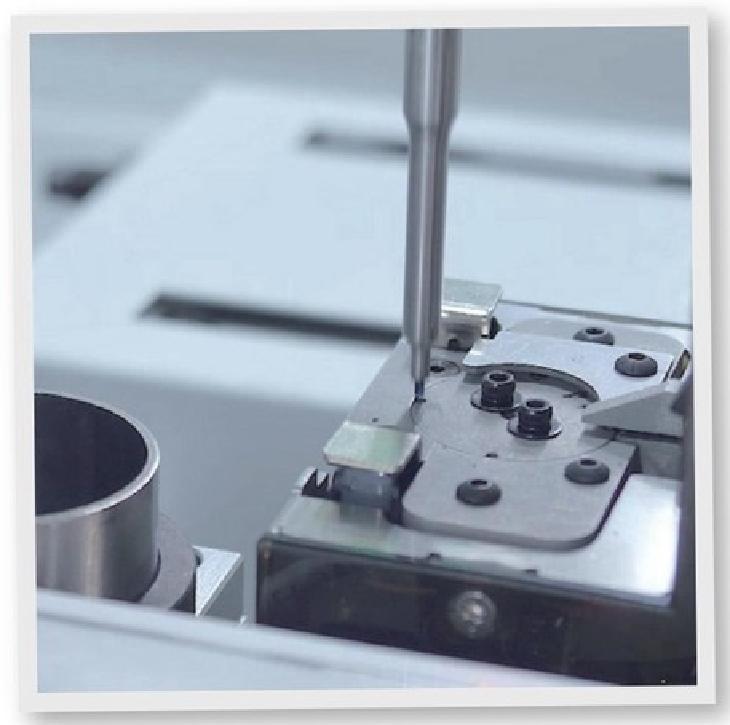

3C Electronics For mobile phones,tablets,conuters and other consumer electronics products to provide automatictightening,automatic assemblyflexible solutions.

-

Energy storage Provide automatic deep hote tightening solution for small energy storage equipment.

-

Power tool Provide automatic intelligent screw tightening solútion for power tools.

-

Automobile Provide intelligent screw tightening solutions for automotive parts,interior parts,automotive electronics,etc.

DO YOU KNOW

WHY CHOOSE US

WHAT IS THE DIFFERENCE BETWEEN INTELLIGENT TIGHT AND PAYMENT ROBOT?

-

Exclusive for micro screws Specially designed for micro screw research and development,the smallest can support M0.6 screw tight,the pursuit of more accurate;

-

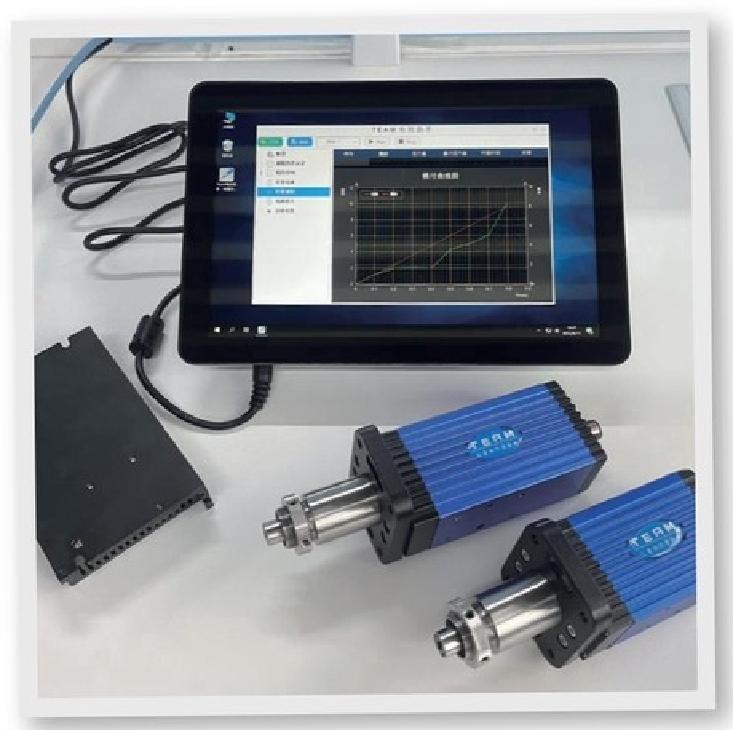

Controllable core process Independent research and development of core components and control algorithms,torquecontrol accuracy up to 3%,to achieve a more professional;

-

The tight payment yield is higher Own tight payment software,real-time monitoring of tight payment process,more Tactic slip-tooth,foat-height detection,yield up to 99.95%,to achieve a more stable;

-

Complex scenarios apply Explore the actual tightening scenario,and developsuitable products for special scenarios such asinterference,countersink,side,etc.,

which aresuitable for more complex ;

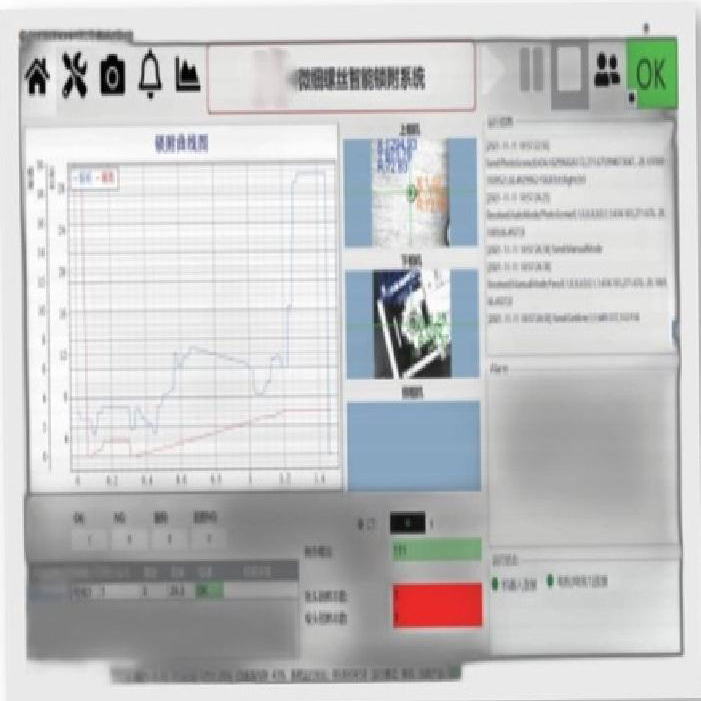

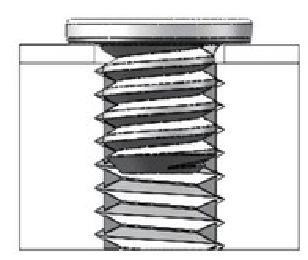

| DETECTION OF TORQUE,NUMBER OF TURNS, | ||

| FLOATING HEIGHT,INCLINATION AND SLIPPAGE | ||

|

Result judgment OK | |

| Set torque:√ Set number of turns:√ |

For example,set the torque value to 1Nm and tight the number of turns to 10. After the tightening procedure is executed,the real-time monitoring data is fed back. When the torque value reaches 1Nm and the number of turns reaches 10 turns,the software judges that the tightening result is OK and outputs an OK signal. |

|

|

Result judgment NG | |

| 1、Floating height detection | ||

| For example,set the torque value to 1Nm and tight the number of turns to 10.After the tightening procedure is executed,the real-time monitoring data feedback shows that the torque value reaches 1Nm and the number of turns is only 5.At this time,the software judges that the tightening result is NG and the NG category is floating high,and outputs NG signal. |

||

| Set torque:√ Set number of turns:× Judgment result:floating height |

||

|

2、Sliding tooth detection | |

| For example,set the torque value to 1Nm and tight the number of turns to 10. | ||

| After the tightening procedure is executed,the real-time monitoring data feedback shows that the number of turns has reached 10, and the torque value has been less than 1Nm. At this time,the software judges that the tightening result is NG,and the NG category is idling (sliding thread),and outputs NG signal. |

||

| Set torque:× Set the number of turns:√ Judgment result: Idling (slippage) |

||